class ii division 2 group g

See answer and applicable Code reference. What is accepted in the USA.

Class II because of combustible dust.

. Division I because dust is present during normal operation. Class I Division 2 Group D. As required by Underwriters Laboratories and Canadian Standards Association explosion-proof motors with Class II Group F G approvals must have over temperature protection.

E combustible metal dusts F combustible carbonaceous dusts or G other combustible dusts. Class II Group F Atmospheres containing combustible carbonaceous dusts such as coal carbon black charcoal and coke dusts. Class i div 1 abcd class iiiii div 1 efg atexiecex g zone 1 iic d zone 22 iiic series 5c valve status monitor nec class i div 1 abcd class ii div 1 efg atexiecex g zone 1 iibh2 d zone 21 iiic series 63 solenoid nec class i div 1 abcd class ii div 1 efg intrinsically safe products12 energy limited ex ia series 6a positioner.

Jun 17 2009. Featuring fully grounded static dissipating designs that are guaranteed. I recognize that temperature limitation will always apply however dust accumulations are not permitted in a Division 2 environment.

The specific hazardous materials within each group and their automatic ignition temperatures can be found in Article 500 of the National Electrical Code and in NFPA 497. Groups E F and G are for Classes II and III dusts and fibers or flyings only. If the substance or concentration in the oxidizer is either below a specific value lower flammability limit or above a spe cific value upper flammability limit.

They are calling it Class II Div II group G My question is do I have to use explosion proof receptacle or do they make something more. NFPA Standards used by Tiger-Vac. Group A includes only acetylene a colorless hydro-carbon gas that creates an intense explosion when ignited.

Class I because of flammable vapor. Class II Division 2 Archives - Ruwac USA. For outdoor application in Class II Div2 Group G you can very well use combination of NEMA 4 very approximate equivalent to IP 66 NEMA 9 For hazardous locations enclosure.

Class II Group G Atmospheres containing combustible dusts not included in Group E or Group F including flour grain wood plastic and chemicals. Class II locations are divided into three groups EFG. In Class II Div.

As you can see by the breakdown Groups A B C and D are for Class I gases only. D a or b. NEC Group G refers to an area that contains combustible dusts that are not included in Groups E and F such as flour grain sugar wood starch chemicals and plastics.

Article 502 covers the requirements for electrical and electronic equipment and wiring for all voltages in Class II Division 1 and 2 locations. Class II Division 12 Groups F. All IP67 rating equipments can not be used in classified area.

Division II because flammable vapor would only leak from the tanks if there was an accident. Propane tank storage room. Class I and Class II locations are further divided into groups based on the behavior of the hazardous material after it has been ignited.

1 locations provide electrical controls eg switches breakers control transformers and resistors with enclosures identified for use in the location 502115 502120. Protection Techniques for Hazardous Areas. The correct answer is.

Group D because propane is in the atmosphere. Would be acceptable for a Class II Division 2 Group FG hazardous area. Ruwac recognizes the seriousness of the potential deadly hazard found in combustible dust and offers a complete line of electric powered explosion proof vacuum systems for Class II Division 2 Environments.

Class II Division 1 Group E. Group G because grain dust is in the atmosphere. Class II Div II receps in cabinet shops Ive been reading a lot on article 502-115 502-145 and speaking to the local authorities on the requirement for receptacles around wood working equipment.

The most common groups and materials are listed below. We have experience in large turnkey solutions for Class 1 Division 2 and ATEX Zone 2 environment projects be sure to give us a call 44 0 1785 879 050 UK or 1 864 421 6991 US to discuss yours. I cannot find any reliable source to come out and specifically say that NEMA 12 or NEMA 4 enclosures are suitable for use in Class II Division 2 Group G environments.

Three Phase TEFC Explosion Proof Class I Div 1 2 Group D and Class II Div 1 2 Groups F G environments Group E available 230460360. Class II combustible dusts are grouped into one of three 3 groups. Groups A B C and D are used for Class I environments Groups E F and G for Class II areas.

Class II locations are those that are hazardous because of the presence of combustible dust. We offer a comprehensive solution service which includes extrusion design manufacture software programming and project management support. NEMA Type 9 enclosures dust ignitionproof are also accepted Reading the above it would appear that a NEMA4 enclsoure and operators lights etc.

C lass I flammable gases and vapors are grouped into one of four groups Groups A B C or D based on their physical properties and the ease in which they can be ignited. Locations with combustible dusts. Per the National Electrical Code NEC there are 3 classifications for areas that are defined as hazardous.

Class II Division 1 Group E - Certified for the safe recovery of Group E metal fines by submerging 100 of the intake air in a liquid bath. 28 SQFT Microclean Technology. Ruwacs Conductive Series General Housekeeping Vacuums are NFPA 652 compliant for ordinary locations.

The ignition temperature of the dust the electrical conductivity of the dust and the thermal blanketing effect the dust can have on heat-producing equipment such as. Class II location groups are determined by. Note that the dust must be present in.

A RMC and IMC b EMT c ENT d a or b. NEMA and UL designations for dusttight equipment are Types 3 3S 4 4X 6 6P 12 12K and 13. Raceways permitted as a wiring method in Class II Division 2 locations include _____.

Locations with ignitable fibers and flyings. Zone 2 Group IIA. The Class 3 motor is the least common and isnt divided any further into groups.

They are Class I gases vapors Class II flammable dusts Class III fibers the focus of todays Blog is on Class II locations. Every flammable gas or vapor has specific lower and upper flammability limits. ClassDivision Hazardous Location 6 Note.

Class II Division 2Group G Switches McMaster-Carr Actuator Style Toggle Push Button Lever Rocker Plunger Roller Lever Foot Pedal Key Rotary Slide Hinge Finger Touch Dual Switch Roller Lever Roller Plunger Mat Cable Pull Toggle with Mini Slide Dimmer Joystick Ball Roller Cross Roller Plunger Dual Simulated Roller Wobble Stick Rod Thumbwheel. 2 provide this equipment with enclosures that are dusttight or identified for the location 502115 502120. Motors suitable for Class II Groups F G Division 2 are available in TEFC TEFC-XT TEBC TEAAC and TEWAC only Any grounding provisions must be in the main conduit box Motor accessories must be non-sparking or approved for Explosion Proof XP duty Ambient may not exceed 60C make addition for higher than 40C ambient as required.

Groups E F and G are for dusts and flyings Class II or III. However Class 1 and 2 motors are grouped by your specific hazardous substance. Class II Division 2.

Class II Group F G locations are atmospheres containing dust such as F Carbon Black coal or Coke Dust G Flour Starch or Grain Dusts.

The Best Headlamps For Hazardous Environments In 2021 Underwater Kinetics

Shared With Dropbox Phonics Digraph Reading Strategies

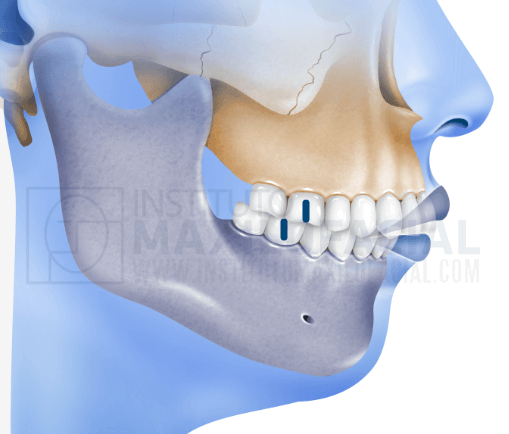

What Is A Class I Class Ii Or Class Iii Bite Instituto Maxilofacial

Non Surgical Compensation Of Skeletal Class Iii Malocclusions Oral Health Group

Ul And C Ul Hazardous Areas Certification For North America Ul

What Is A Class I Class Ii Or Class Iii Bite Instituto Maxilofacial

Ul And C Ul Hazardous Areas Certification For North America Ul

Ul And C Ul Hazardous Areas Certification For North America Ul

Ul And C Ul Hazardous Areas Certification For North America Ul

Origin And Early Evolution Of The Plant Terpene Synthase Family Pnas

Surgical Wound Classification Grades As Defined By The Cdc Download Scientific Diagram

Ul And C Ul Hazardous Areas Certification For North America Ul

Ul And C Ul Hazardous Areas Certification For North America Ul

Origin And Early Evolution Of The Plant Terpene Synthase Family Pnas

Self Regulating Heating Cables Approved For Use In Hazardous Locations Briskheat

Ul And C Ul Hazardous Areas Certification For North America Ul